Rumored Buzz on Steel Road Plates

Steel plates are supply an excellent, short-term solution for covering hazardous holes on a building site. These sturdy, durable plates enable roads to return to solution to ensure that construction can proceed. Below we check out the layout details and best practice setup suggestions. These plates can be made use of to ensure that roadways can still be utilized whilst other stages of job continue.

They supply a suitable concession for keeping lanes, whilst work continues over night and at weekends. They are usually seen when excavations have actually begun as a very early phase of construction or repair service projects. These plates are created to hold up against sturdy usage on hectic roads. They include an akti-skid layer and are offered in a variety of colour coatings - Steel road plates.

The weights start from around 300kg and typical roadway plates have a thickness of either inch or inch. The capability to be bolted to the roadway.

The smart Trick of Steel Road Plates That Nobody is Talking About

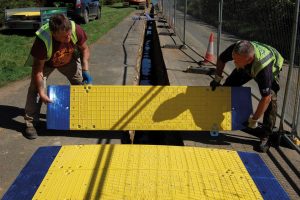

Hinged variations for quick accessibility to the excavation or routine access, e.g. driveways. Composite plates, which can fit various lengths of trench. Skid-resistance for improved vehicle, pedestrian and website employee security. Steel roadway layers can be mounted rather rapidly, yet they are hefty. Therefore, they must be set up utilizing a forklift or crane.

Check for displacement by traffic packing from the beginning plates ought to always stand up to variation. Inspect that home plates do absent a danger to any type of roadway individual and can be utilized by all roadway individuals and automobile kinds, consisting of pedestrians, bicyclists and motorcyclists. Develop a normal examination and upkeep to make sure that performance stays secure and optimum.

Repair home plates properly in all times. Mechanical lifting guarantees that the plates are mounted accurately and securely. The right plates need to appropriate for the wanted objective Think about ideal safety zones, particularly when intending installation. The weight of home plates can cause swinging in the building location or across neighbouring carriageways/ footways.

If a ramp is created by the road plates, after that advising signs for pedestrian and roadway customers are required. Constantly a conduct full site survey, and take the expert advice of an architectural designer. The Division of Transport also supplies advice on setting up road plates, please visit this site. SafeSite Facilities (Steel road plates)' road plates are available for buy or hire throughout the UK.

Unknown Facts About Steel Road Plates

In order to improve security, there are a variety of requirements and market papers leading their usage in building and construction job zones. This post provides some highlights that may be helpful in beginning your investigation. If you need additional info, please call our expert directly. Steel plates need to be taken care of in area to prevent movement.

Our Steel Road Plates PDFs

Along with being strongly touching the sidewalk, they must be either pinned, recessed right into the sidewalk, or safeguarded with asphalt wedges around the border. Pinning into the sidewalk includes driving pins right into the sidewalks along the edges of the steel plates to protect against activity. Recessing entails reducing out the area where the steel plate will certainly be put.

This causes the steel plate being flush with the sidewalk. Furthermore, when numerous steel plates are made use of and butt up to each other, they must be welded with each other at the longitudinal seams. Steel plates can be very slippery, specifically when they are wet, unless they have an anti-skid coating applied.

Covering steel plates with a material that boosts friction helps motorcyclists and bicyclists maintain control, specifically in damp weather condition. Conditions which reduce pavement rubbing in work areas are of certain concern to motorcyclists and bikes. A typical risk in steel plate setups occurs when the customer stops working to create properly tapered ramps from the roadway to the sides of the steel plate( s).

An Unbiased View of Steel Road Plates

It positions a significant risk to motorcyclists and bicyclists that can quickly shed control when they contact the abrupt/steep tapered ramp and the steel plate. Effectively conical ramps enable individuals to securely go across over the steel plates.

Department of Transport's Federal Highway Administration (FHWA) calls for that transverse pavement joints, which lead to a bump, must be tapered at 60 to 1 (5 feet horizontal for every single 1 inch of upright elevation distinction). Select the proper size. Make certain ample overlap. Generally, steel plates need to prolong at the very least one foot beyond the sidewalk opening onto company ground.

The Greatest Guide To Steel Road Plates

Welding is utilized when even more than one steel plate is made use of and they butt as much as each various other. Plates need to be countersunk when needed due to uneven roads. Plates need to be covered with an anti-skid covering. The sides of the steel plates ought to be marked/painted to boost Steel road plates exposure. Appropriate development indication should be used.

His history includes the building, assessment, learn more.

In the world of civil engineering and building, steel roadway plates are a quintessential tool that holds tremendous importance. These heavy-duty steel plates play an essential role in improving building and construction safety, providing momentary streets, and guaranteeing smooth operations on different project sites. As a building and construction devices vendor, their importance can not be overstated.